measuring gold plating thickness|gold plating thickness standards : agency XRF coating thickness measurement is a necessity for the $10 billion metal finishing industry. It is also the technology tool that allows contract platers, whose margins are always under pressure, to deliver high quality coatings at lowest . Resultado da Participa en los sorteos de Navidad, El Niño y el resto de sorteos de Lotería Nacional. Toda la información aquí

{plog:ftitle_list}

Resultado da SCREW translate: 金属物体, 螺丝(钉), 扭转,旋转, 监狱看守, 监狱看守(尤为犯人用语), 发生性关系, 性行为;性伙伴, 器具, 金属物体, 用螺丝固定(或拧紧), (用类似螺丝的东西)固定,拧紧.. Learn more in the Cambridge English-Chinese simplified Dictionary.

Luxury quality watch cases from some manufacturers have been plated in gold (18 kt color) up to 20 microns (1/50 of a millimeter) in thickness. This by far exceeds the 2.5 microns required for “heavy gold plate” under .XRF coating thickness measurement is a necessity for the billion metal finishing industry. It is also the technology tool that allows contract platers, whose margins are always under pressure, to deliver high quality coatings at lowest .

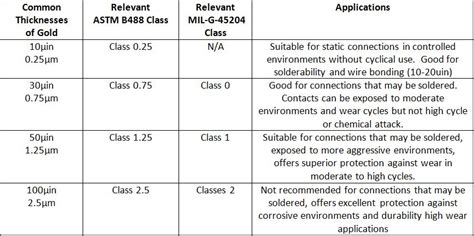

Here’s a look at gold plating thickness standards for connectors so that you’re able to design gold plating at the minimum thickness for performance and cost savings. Gold Plating Thickness for MIL-DTL-45204D and ASTM B488. MIL-DTL-45204D, as you likely know, is a technical military specification for gold plating.APPENDIX 4 Recommendation For Thickness Measurement... 10 APPENDIX 5 Standard Developments Efforts of Electroless Nickel Immersion Gold . Gold Plating ... 1 Table 4-1 Qualification Test Coupons ... 6 IPC-4552 with Amendments1&2 December 2012 .Measuring Plating Thickness . Plating used on electrical component leads and as printed-wiring-board finishes is usually thin, less than 300 micro-inches, and it is important to verify that the plating thickness meets specifications. . Gold plating thickness over nickel or nickel-phosphorus alloy can also be determined by SEM Lab, Inc. using .

Plating, the process of covering a substrate with a thin layer of metal, plays an essential role in modern manufacturing and materials science. The thickness of the plating layer is a critical parameter that can significantly impact the finished product’s performance, durability, and aesthetic qualities. In industries where precision is non-negotiable, such as aerospace, .SGS MSi can perform plating thickness testing using SEM and optical microscopy and testing to ASTM B748, B747, E3-11 and A90. . Gold; Nickel; Copper; Chromium; Chro; Cadmium ; . ASTM A90 Coating Weight Determination. ASTM A90, is the analytical method for measuring the amount of zinc coating applied to a steel product for a specified .

An electroless nickel coating is uniform; it will not build up on corners or projections. The deposited metal layer has an even thickness over all surfaces of the component regardless of its shape; this cannot be achieved with electrodeposited coatings. Typical thickness of electroless plating can be as thin as .0005" and up to.010".

If only a few micrometers of gold can be saved, the measuring instrument is amortized within a very short time and actively supports you in saving costs! . AN017 Automated coating thickness measurement in production facilities 0.73 MB AN030 Saving costs by using inline measurement for electroplating reel-to-reel applications .gold flash – 10 kt gold with a minimum thickness of .175 microns. gold electroplate – 14 kt or higher gold layer with a minimum thickness of .175 microns. gold plate – 14kt or higher gold layer with a minimum thickness of .5 microns. heavy gold plate – 14kt or higher gold layer with a minimum thickness of 2.5 microns. The items subsequently have a precious metal coating applied to them (silver or gold) which tend to increase the visual aesthetics of the component but keep the manufacturing costs low. The cost benefits can then be passed to the consumers. . Although an easy to use and highly versatile method for coating thickness measurement, the sample can .

Note: The density of gold plating can range from 11.3mg/in2 per micron thickness through 12.45mg/in2 per micron thickness. the upper end of the range is for a very fine grain gold plate. Measuring Units for the thickness of gold plate: The English term is "micro-inches" (millionth of .

This is especially true if the point of thickness measurement is at the end of the part or on the inner diameter. In these cases, choosing the correct point of measurement (POM) is critical. . We specialize in plating of gold, silver, rhodium, palladium, nickel and tin-lead using a variety of techniques including barrel, reel-to-reel .It includes specifications for gold plating thickness, adhesion, and other relevant characteristics. MIL-PRF-55110G. . Besides, it also includes thickness measurement. Conclusion. We can see that gold is such a precious metal and has its importance in the electronics industry. It is one of the commonly used surface finishes in PCBs. The measurement of bold plating is the most important application for X-ray fluorescence (XRF) plating thickness measuring instruments. Gold is plated on a variety of copper-alloy and iron-alloy substrates, and often over interlayers such as nickel, silver, and palladium-nickel. The applications include a wide assortment of electronic devices .Verification Process and Standards in Measuring Plating Thickness. Verification process and standards are important in measuring plating thickness accurately. The verification process is used to make sure that the measurements taken with the plating thickness measuring device are accurate and meet the standards set by the industry.

The change in the rate of beta particles scattered is a measure of coating thickness. This method is used for measuring gold, silver and tin on electronic components; decorative plating on plumbing fixtures and vapour-deposited .

Sample: One plated area 0.010 inches (0.25 mm) in diameter or larger. Basic Description: ASTM B568 X-Ray Fluorescence (XRF) is a non-destructive method of measuring plating/coating thickness by using an X-ray beam to excite the surface of a sample and then calculating the intensity of the energy returned by the plating versus the base material. Each element emits .a non-uniform thickness layer thus exacerbating the problem. The definition of thickness as applied at APC is the purpose of this monograph. Plating Thickness Deposit thickness applied by barrel or rack techniques and by either of electrolytic or electroless methodologies is normally distributed. The normal If the gold coating thickness increases, the backscatter rate increases. The change in the rate of electrons reflected is, therefore, a measure of the coating thickness. The test specimen has to be placed on an aperture, so that a defined surface area is exposed to the electron radiation.

Plating Thickness: AMS QQ-P-416 . AMS QQ-P-416 remains the gold standard for industries where performance and reliability remain non-negotiable. . Thickness Measurement: Precisely measuring the cadmium layer thickness ensures adequate corrosion protection without compromising dimensional tolerances.

cycles, reducing agents, and equipment. In addition, electroless plating provides uniform thickness and deposits, especially in deep recesses, bores, and blind holes. Alternative plating methods such as PVD, CVD, and thermal spraying reduce the amount of contaminated wastewater produced by plating, but have high unit-plating costs. 3.0 COATING .

The Vanta handheld XRF analyzer can measure coating thickness from 0.00 to approximately 60.00 microns, depending on the material. X-rays are emitted from the analyzer, and they strike the sample, causing it to fluoresce. The analyzer detects the returning X-rays and uses the data to calculate the thickness of the coating or coatings.teristic x-rays from only that coating (i.e., gold) occur. The countrate within this ROI will increase as the thickness of the layer increases, up to the point of saturation of infinite thickness.5 By taking countrate data on reliable thickness standards and fitting the data to a calibration curve, the constants defining the thickness curve are .Measurements of coating thickness are based on the fact that the time required for this process is proportional to the plating thickness. Can measure thicknesses of many types of plating, and can determine individual film thicknesses for multilayered plating. Cannot measure small items or sites with complex shapes. Magnetic force methods

The well‐established X‐ray instrumentation for coating thickness measurement, with proportional counter detectors, are not very suitable for measuring thin ( < approx. 100 nm) coatings of gold and palladium due to the poor energy resolution of the .An electroless nickel coating is uniform; it will not build up on corners or projections. The deposited metal layer has an even thickness over all surfaces of the component regardless of its shape; this cannot be achieved with electrodeposited coatings. Typical thickness of electroless plating can be as thin as .0005" and up to.010".It can measure the plating thickness on large and fine-pitch conductors of a variety of plating finishes: tin-lead (Sn-Pb), immersion silver (ImAg), immersion tin (ImSn), electroless nickel immersion gold (ENIG) and thick gold (Au).

what is heavy gold electroplate

Adhesive Peel Tester Brand manufacturer

Adhesive Peel Tester wholesaling

WEB3 dias atrás · UWin777 is available on. Mobile Site. Consumer today live and play in real-time world without restrictions, and so do we. We firmly believe that's user's gaming experience should be the same no matter what the content, where and when it is played, and regardless of the device they choose to play on. Go to Mobile Site.

measuring gold plating thickness|gold plating thickness standards